AngioDynamics’ Gen 4 Cannula Case Study

Advancing Pulmonary Embolism Intervention

Problem

Interventional cardiologists using AngioVac Gen 3 reported limited reach and flexibility when navigating tortuous vasculature to remove emboli from the pulmonary artery. The existing system lacked precision, with components behaving like a “slinky,” complicating deep navigation and control during thrombectomy procedures.

Solution

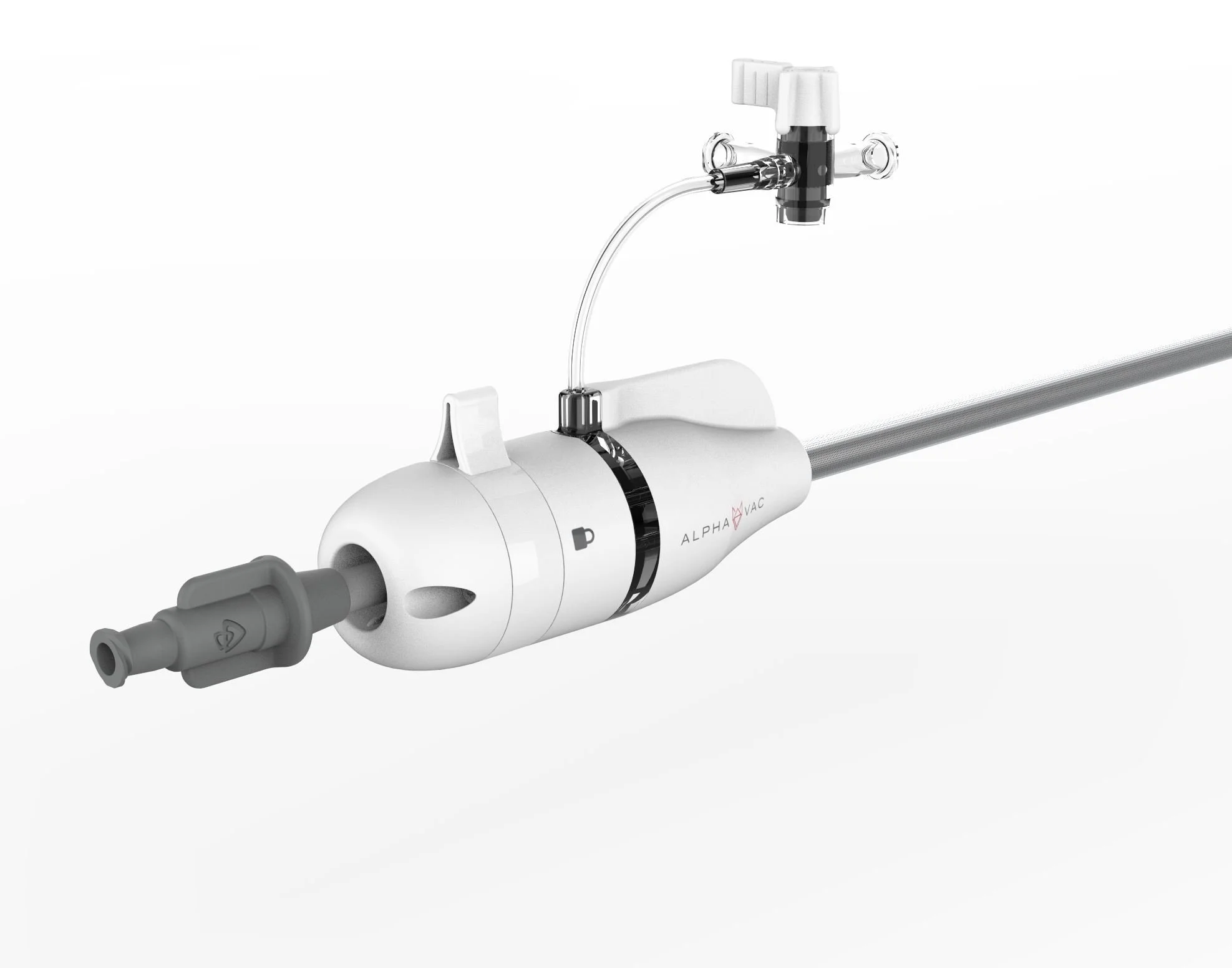

HaA PD redesigned the cannula with a lower profile, braided dual-durometer shafts, and an angled tip for improved flexibility and control. We refined component lengths and geometry through simulated vasculature testing, enabling reliable navigation and retrieval from both jugular and femoral access points.

Outcome

AngioDynamics is a major player in the thrombectomy market due to AngioVac, and was granted Breakthrough Device Designation by the FDA for the AngioVac System to include non-surgical removal of vegetation from the right heart. Thanks to our collaboration, AngioVac is saving lives and propelling AngioDynamics forward as a leader in the medical device community.

Services Provided to Develop AngioDynamics’ Gen 4 Cannula

Research

HaA conducted an alignment exercise that uncovered many questions related to the product, procedure, and the sources of information within the company. This helped to focus the team on what answers were needed and where those answers would be obtained.

Analyzed failure modes in current procedures and ensured that we captured critical needs.

Usability

Reviewed procedural videos and documentation to evaluate product usage

Identified unmet needs in the market to ensure the product met the needs required for success.

Multiple usability feedback sessions were conducted with a range of physicians. HaA was able to create a unique test system that allowed the device to be used realistically without needing fluoroscopy or animal or human specimens.

Workflow Optimization

Mapped the full surgical procedure to pinpoint failure points.

Streamlined workflow to reduce complexity and enhance efficiency.

Program Management

Based on experience and simple math, we were capable of estimating part cost at the onset of the project allowing for proper budgetary planning.

Developed a detailed summary of the project, including milestones, product cost targets, pre-engineering tooling costs, and estimated testing costs.

Engaged with partner vendors early to ensure realistic, real-world cost projections.

Project Management

Managed the project timeline from start to finish, assigning roles and responsibilities of both internal and external resources.

Regulatory Compliance

Operated within the company’s Quality Management System (QMS).

Supported and provided regulatory documentation and work instruction development.

Industrial Design

Sketched initial concepts and built CAD models.

Down-selected designs based on human factors, environmental needs, and product workflow.

Developed graphics, color material finish and branding.

Final designs balanced form, fit, and function.

Engineering

The HaA engineering team designed multiple iterations of the device and worked closely with high capability contract manufacturers to make sure the device could be made repeatedly and within specifications.

CAD Development

Developed detailed 3D CAD models based on final product specifications.

Prototyping

As part of our prototyping services, we built fully functional units for animal trials and testing, and to fuel stakeholder confidence.

HaA prototyped parts using various methods including 3-D printing, laser cutting, and CNC machining. The team worked closely with the final component suppliers to make sure prototype designs were easily transferable to manufacturing.

Testing

Testing a catheter that needs to navigate to the right heart is a challenge. HaA worked closely with vasculature molding suppliers to create a one-of-a-kind test system that allowed the team to refine the design faster and more accurately. The test system also allowed for user practice and feedback that would have been difficult to obtain otherwise.

Manufacturing Support

Identified appropriate laser cutting, extrusion, catheter assembly, and injection molding manufacturers for scalable production.