Medical Device Design

The design of medical devices can be complex and challenging, as it must balance clinical performance, user and patient safety, medical regulations, and product design manufacturability. The end product is a device that works seamlessly, advances technology, and improves patient outcomes. A quality device aligns with clinical workflows and withstands rigorous testing and regulatory audits.

Why It Matters

Well-designed medical devices reduce risk in patient care. Poor ergonomics, complicated user interfaces, or unclear clinical workflows can lead to user errors, delayed treatment, or even patient injury. In the medical industry, there is no room for device or user error due to poorly designed devices.

Equipment must function effectively in high-stress and high-pressure clinical environments. Design must be intuitive for busy clinicians to effectively treat patients with. The device must also integrate seamlessly into existing systems of the clinical environment. A perfectly functional design that only works well in theory, but not in a real hospital setting is useless.

Further, medical devices and medical device development must comply with strict regulations. Before a medical device can enter the market it must pass strict design controls, performance verification and risk management, and, in some cases, clinical or performance verification, then be submitted for FDA clearance or approval. Poor design or cutting corners can lead to problems being uncovered in these steps which can create costly redesigns, regulatory resistance, delays, or even complete recalls, which can damage your business's reputation and dramatically increase your required budget..

What makes a well-designed device? It is easy to manufacture, cost‐effective, intuitive to the user and clinically safe and effective. Good design and engineering seeks to identify areas where costs can be saved and manufacturing can be streamlined for consistent, cost effective, repeatable production . It also seeks to reduce waste and can be scaled up at competitive prices to meet the company’s growing needs. In summary, design is not only usability or aesthetics, it impacts every stage of a medical device's development process.

Our Approach

Our planned and organized process for medical device development makes sure that every project or program results in devices that are safe, regulatory compliant, and perform flawlessly, while maintaining an appearance that is visually pleasing and represents your brand. Additionally, our process ensures that your device can be easily manufactured with top quality and cost effectiveness in mind.

Discovery & Research

We begin our design by considering all possible and necessary user needs, including those of clinicians, patients, and stakeholders. We work through clinical processes and observe actual settings. We also conduct interviews with stakeholders and gather both qualitative and quantitative data to determine the best design for this particular device. We then assess risk and evaluate the industry standards. Finally, we study the competition and how they have established their industry benchmarks.

The above information, combined with the device's technological environment, forms the basis for our design decisions.

Concept Development

Our research informs us about the best design, but our quest for perfection doesn’t end there. We continue the device development process by refining design concepts and creating form factors, interaction patterns, hardware layouts, and user interface ideas. Early sketches, mock-ups, and low-fidelity prototypes help us verify the feasibility, usability, and viability of our designs. In addition, we work closely with stakeholders from the earliest stages, so that their feedback is incorporated before significant investment is made.

Design Iteration

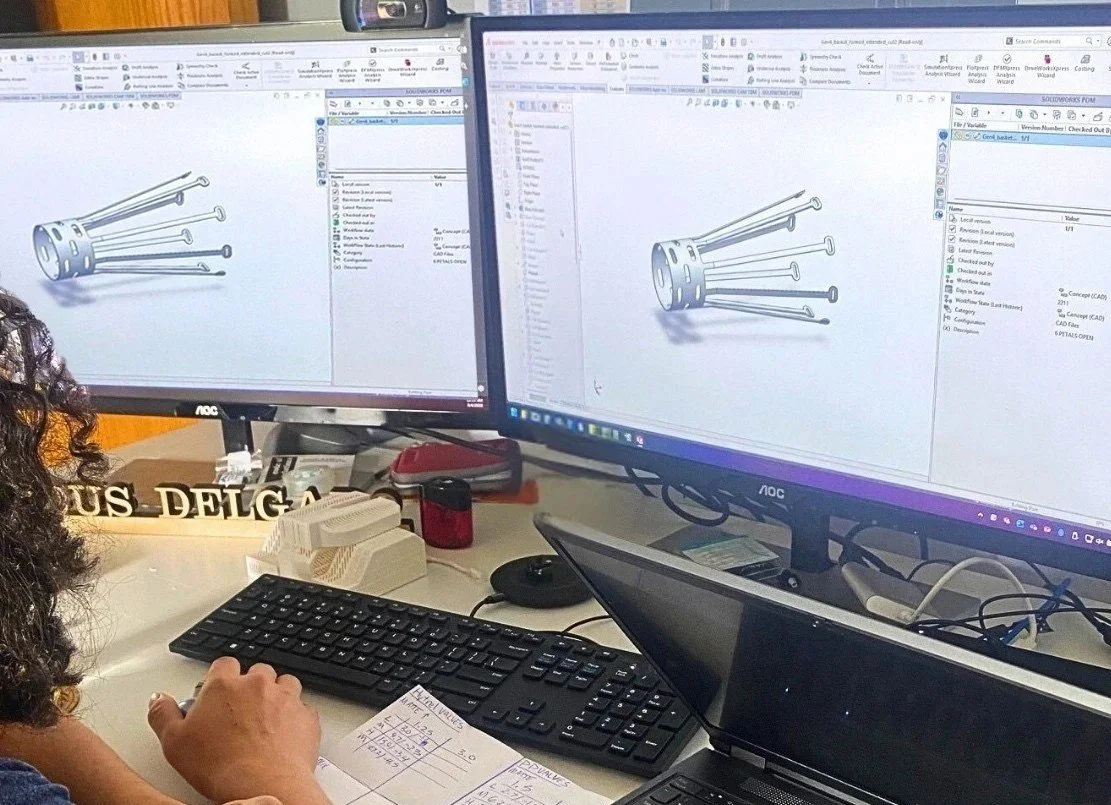

After narrowing down our design choices, we then assess detailed component costs, manufacturing and formative feedback to further iterate our designs. We create accurate models and test them for performance and usability. We focus on the industrial design (CMF: color, material, finish), optimize for usability, and verify that the product can withstand normal usage conditions (including sterilization, cleaning, and repeated use). We make trade-offs among cost, performance, reliability, and user experience when refining both hardware and software elements.

Verification & Handoff

Before any large-scale engineering begins, we confirm that the design meets all requirements, including usability, safety, performance, regulatory compliance, and manufacturability. We conduct usability testing, risk analysis and assessment, design reviews, and compliance checks. We then put together the documentation package for manufacturing handoff, which includes detailed drawings, BOM, work instructions, and, when required, software specifications. We collaborate closely with our manufacturing partners for a seamless transition into production.

Integrated design capabilities

Here are some of our more specialized services:

Medical UX Design

We create clinical workflows to view user tasks in context, and conduct formative and summative usability testing to validate safe, effective, intuitive experiences. (Learn more about Medical UX Design)

Medical UI Design

We build information architecture, establish interaction patterns, and determine display logic to present clinical information simply and reduce cognitive load. (Learn more about Medical UI Design)

Medical Industrial Design

We focus on ergonomics, form factor, CMF (color, material, finish), reprocessing, and sterilization constraints to create devices that are functional and durable. (Learn more about Medical Industrial Design)

Medical Device Prototyping

Iteratively producing prototypes enables us to test feasibility upfront and confirm form, fit and function. We aim for the stakeholders to adopt the new device into their work lives. (Learn more about Medical Device Prototyping)

Compliance & Standards We Design To

We design and meet a variety of regulations and standards, like (but not limited to) ISO 13485, IEC 60601(s) for electrical safety, ISO 14971 for risk management, IEC 62366 for usability engineering, and FDA 21 CFR Part 820, just to mention a few. Our method incorporates design controls, validation, verification, and traceability, establishing compliance as the default setting, rather than an afterthought.

Examples of Products We Designed

Here are examples of our previous design work and product development, and the impact of the devices we produced:

Verb Surgical's Digital Surgery Platform

What we did: Verb Surgical hired us to build a next-generation, robotically enabled surgery system integrating advanced visualization, accurate surgical tools, haptic feedback, and real-time data analytics. Our industrial and interaction design contributed to the system while working closely with engineers and clinicians throughout the design process.

Why: The goal was to increase surgeon precision, avoid fatigue, and help with better real-time decision-making for complicated operations. The combined design provides surgeons with more control and awareness of situations, thereby improving patient safety and outcomes. Our work helped the platform become a market leader in the emerging field of digital surgery.

Boston Scientific's Transbronchial System

What we did: We developed a one-handed aspiration device with offset needle actuation and an integrated syringe vacuum system. The ergonomic design made it easier for physicians to operate the device to conduct lung biopsy procedures.

Why: The new design reduced the number of clinicians needed in the room, decreased procedural time, and streamlined overall workflow. It improved consistency and control of aspiration, and increased safety and efficiency in high-risk clinical environments. The product was optimized to meet the real needs of pulmonologists and interventional radiologists, resulting in high adoption and clinical satisfaction rates.

What You Get

We provide our clients with comprehensive solutions tailored to their specific needs. Our medical device design customers get more than drawings and prototypes. You receive a validated, manufacturable, regulatory-compliant, usability-tested, risk-analyzed design. The outcome is an engineering-ready product that includes test information, specifications, and all necessary documentation to facilitate progression toward clinical and market clearance.

In real-world terms, you receive physical prototypes (sometimes working, sometimes for concept looks), accurate CAD models, mock‑ups of the user interface or software prototypes, usability test results, risk and safety reports, a comprehensive manufacturing‑ready design package, and support during verification activities.

With HaA Product Development, you will get a medical device that combines design innovation with exemplary functionality for your users. Contact us today and let us help you design a device that meets the needs of regulators and can be produced uniformly and at a competitive price!