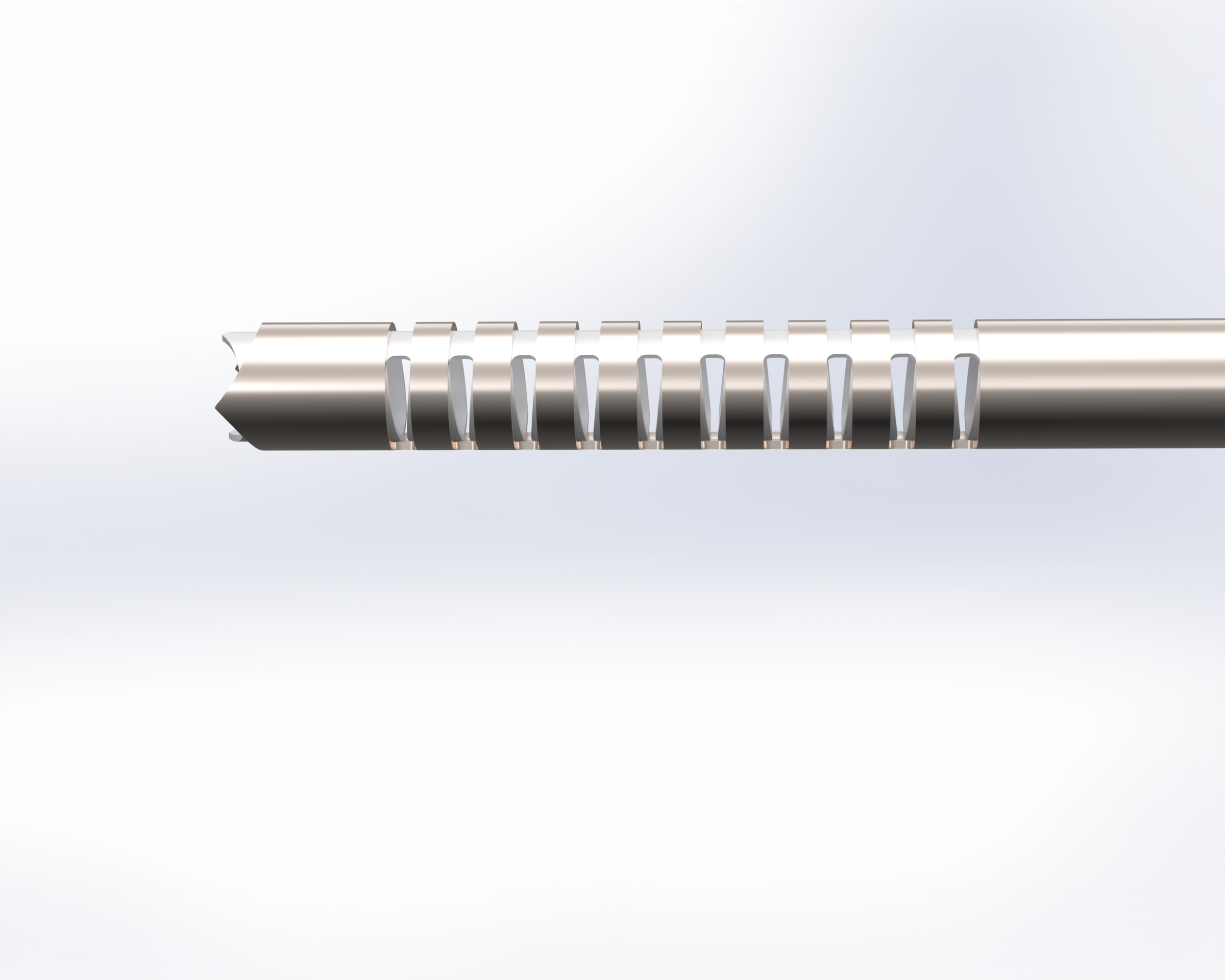

Symmetry’s Steerable Drill Guide

Delivering a High-Volume, Single-Use Precision Mechanism

Problem

Symmetry Surgical required a disposable drill guide featuring a ratcheting lever, spring-loaded handle, and primarily plastic components—without compromising reliability. A clear angle indicator was essential for improved control and accuracy.

Solution

HaA PD refined the design to incorporate robust, plastic-based mechanisms that support reliable ratcheting and efficient high-volume production. A simple yet effective angle indicator was integrated for enhanced precision and usability. The result was a cost-effective, single-use Steerable Drill Guide (SDG) that streamlined surgical procedures while meeting all functional requirements.

Outcome

The Steerable Drill Guide was the first of its kind—disposable, steerable, and equipped with an angle indicator. It was extremely well received by the orthopedic surgery community and set a new standard for procedural efficiency and innovation.

Services Provided

Research

Through our medical device market research, we collaborated with the Symmetry Surgical team to document challenges with the existing manufacturing line

Analyzed failure modes in current procedures

Usability

Reviewed procedural videos and documentation to evaluate product usage

Identified unmet needs, including the lack of disposable and steerable options in the market

Workflow Optimization

Mapped the full surgical procedure to pinpoint failure points

Streamlined workflow to reduce complexity and enhance efficiency

Program Management

Based on experience and simple math, we were capable of estimating part cost at the onset of the project allowing for proper budgetary planning.

Developed a detailed summary of the project, including milestones, product cost targets, pre-engineering tooling costs, and estimated testing costs.

Engaged with partner vendors early to ensure realistic, real-world cost projections.

Project Management

Managed the project timeline from start to finish, assigning roles and responsibilities of both internal (Symmetry) and external (HaA) resources.

Regulatory Compliance

Operated within Symmetry’s Quality Management System (QMS)

Our medical device regulatory compliance team supported regulatory documentation and work instruction development

Industrial Design

Sketched initial concepts and built CAD models.

Down-selected designs based on human factors, environmental needs, and product workflow

Developed graphics, color material finish and branding

Final designs balanced form, fit, and function.

Engineering

Applied our medical device engineering services to select a mechanism that maintained a compact form factor while ensuring full functionality

CAD Development

Developed detailed 3D CAD models based on final product specifications

Prototyping

Built fully functional, sterilizable test units for animal trials

Through our medical device prototyping expertise, we partnered with an injection molding vendor to expedite first article inspections and minimize production risk

Manufacturing Support

Delivered medical device manufacturing support by identifying tooling and injection molding manufacturers.

Ensured scalable production that balanced cost-efficiency with quality.