Insulet’s Omnipod

How HaA PD Improved Cost Efficiency by Simplifying Electrical Connections

Problem

Insulet's core product was too costly to manufacture, putting its market viability in jeopardy. HaA PD stepped in to redesign the product, aligning manufacturing and design to drastically cut costs and streamline production.

Solution

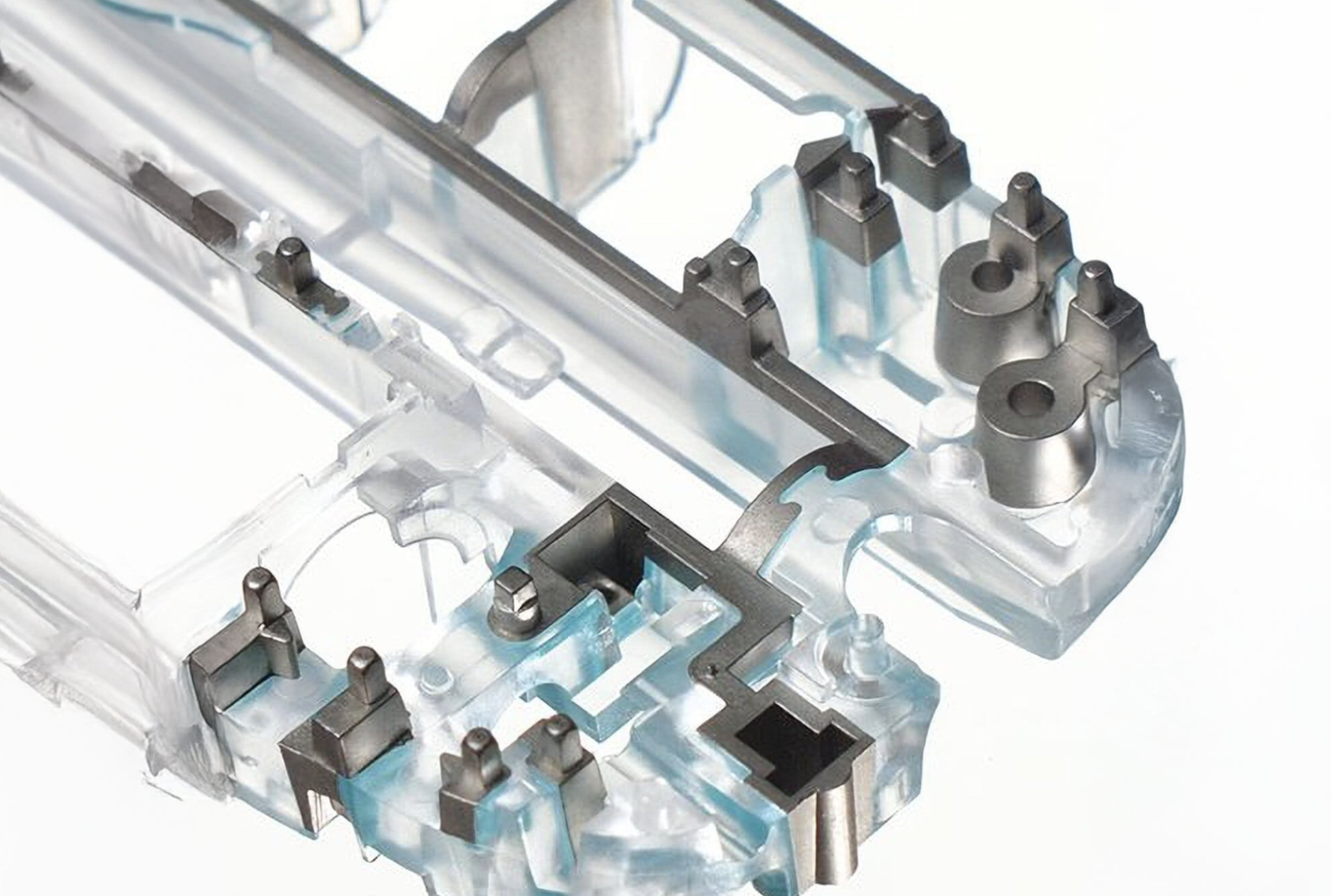

The original Omnipod had a metal lead frame. This was a sheet metal part with many difficult bends. It was very difficult to manufacture. Yield was very low. Tolerances were very high. In short, it was impossible to manufacture. Therefore, the cost was very high.

Insulet management/engineers – the team consisted of 11 engineers, none of whom had the skill set to CAD surface model using SolidWorks with an overmolded gasket. Therefore, the CAD assembly and the Omnipod shell were given to our team to manage. This also included the file management of the entire assembly.

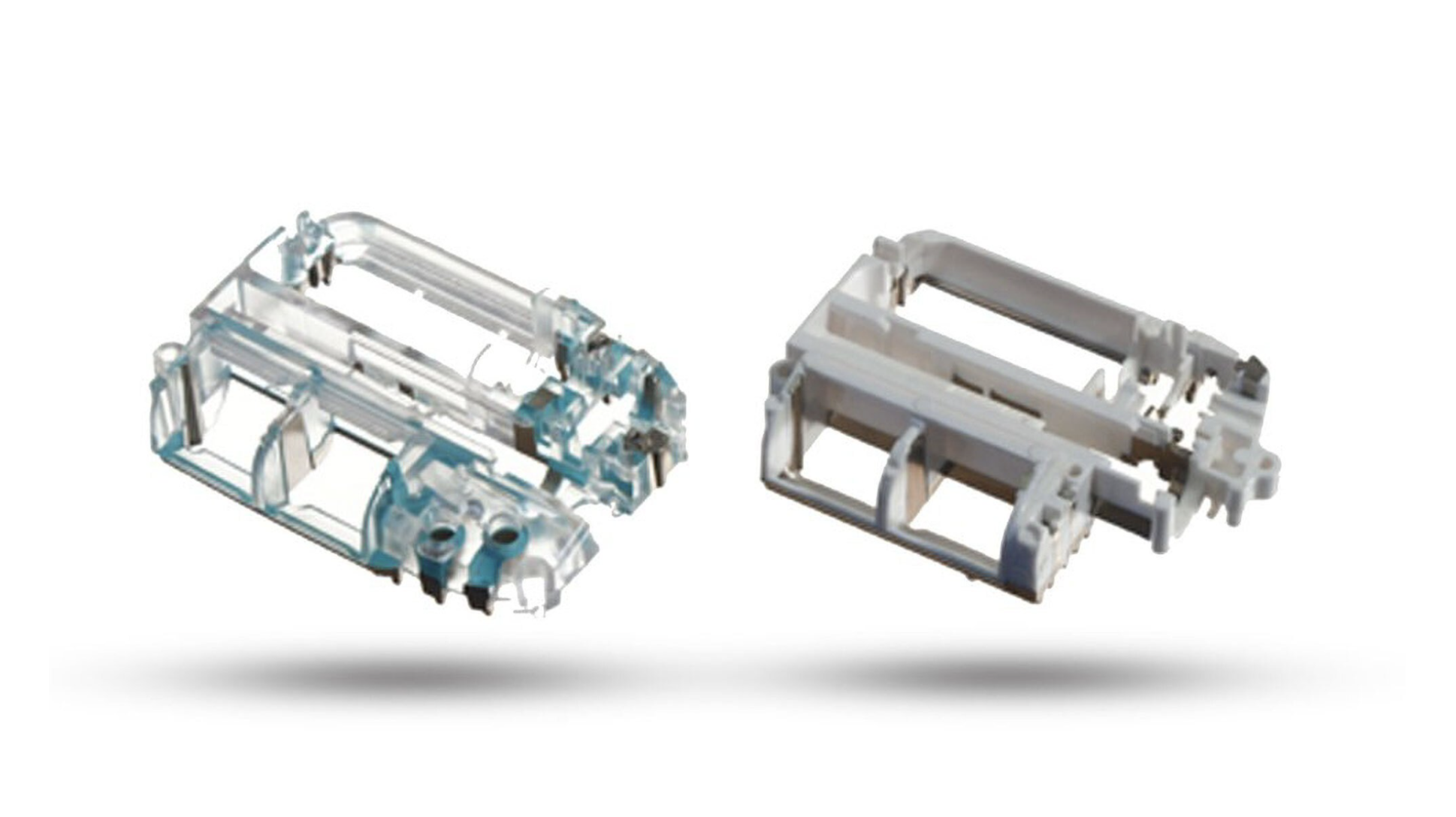

As the project advanced, we recommended that we engage with a company called MGS, which had double-shot injection molding capabilities using dissimilar materials. Since we had experience with this on another project, we were also awarded the lead frame project.

After the lead frame, pod shells, and the overall assembly were completed, organized, and documented (meaning drawings), the database was handed back to the Insulet management team and engineers to begin engaging tooling for production. In parallel, engineering started setting up assembly stations for manufacturing.

The start-to-finish of our medical device development services lasted about six months.

Note - Founder Steven Lepke was the solo engineer for the original Insulet PDM.

Outcome

By introducing a 2-shot molding process for the chassis, we eliminated the need for soldering and automated electrical routing, reducing manufacturing costs from hundreds of dollars to less than $10 per unit. This innovation cut assembly time by over 50% and turned a financially unfeasible product into a market-ready success.

Services Provided to Develop Insulet’s Omnipod

Engineering

CAD engineering using SolidWorks for injection mold design of all double-shot components, as part of our broader medical device engineering services.

Process Refinement

Recommended new manufacturing innovations (as a company, Insulet had never heard of). Recommended and was involved with qualifying the final supplier for tooling. Completed 2D documentation for manufacturing and inspection. Created work instructions and wrote the validation requirements for testing of most of the 75 components.

Manufacturing Support

Supported updates and changes based on findings from the manufacturing team when setting initial production. This included ECOs and CAD changes to improve manufacturing processes.